BP Rotterdam Refinery

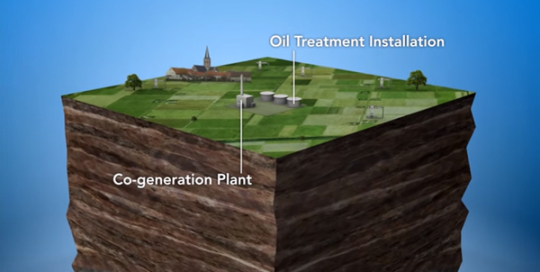

he BP Rotterdam refinery is 100% owned by BP, has a capacity of 377 thousand barrels per day and has two 24MW cogeneration units. It is located on the port of Rotterdam, one of the busiest trading ports in the world. The refinery has two sites; a 390 acre oil processing and offloading facility in Europoort and a 90 acre offloading facility in Pernis.

At the Europoort site, there are 100 storage tanks with a total capacity of 4.3million m3. At this site, produced components are mixed into end products. These are transported by road, water, rail and pipeline where they find their way to service stations, depots and into industry and shipping. At Pernis, a modern tanker dock loads an average of 125 tanker trucks per day with gasoline.

Two challenging projects:

- The HF Alky water Mitigation project

- The FCCU SIS revamp project

– The HF Alky water Mitigation project: For many years the refinery has invested significant effort and capital to reduce the toxic risk associated with potential hydrofluoric acid (HF) releases from its HF Alkylation unit. These efforts have significantly reduced the overall toxic risk associated with refinery’s HF Alky unit. One HF risk mitigation technology that the refinery can improve upon is water mitigation. Water mitigation refers to remote activation and operation of water sprays in the event of small and medium size HF releases, to reduce the concentration of airborne HF leaving the HF Alkylation unit’s plot.

– The main objective of the FCCU SIS revamp project is to upgrade the obsolete DCS/SIS systems of the selected process units and their functions to a new SIS and BPCS system, full fiber connection to the FCCU control room, upgrade field instrumentation and to enable compliance outcomes from the HAZOP/LOPA and other risk assessments.

The goal of both projects is to reduce the following risk to tolerable level:

- Harm to people;

- Environmental damage;

- Commercial loss, including rebuild cost and cost of lost production.

Our activities consists of the EP (Engineering & Procurement) management of both projects